A design for a machine tool attachment was developed in the early 20th century to mill internal keyways in blind or open-ended bores.

Today, we manufacture this same design for modern applications for use on manual or CNC machines.

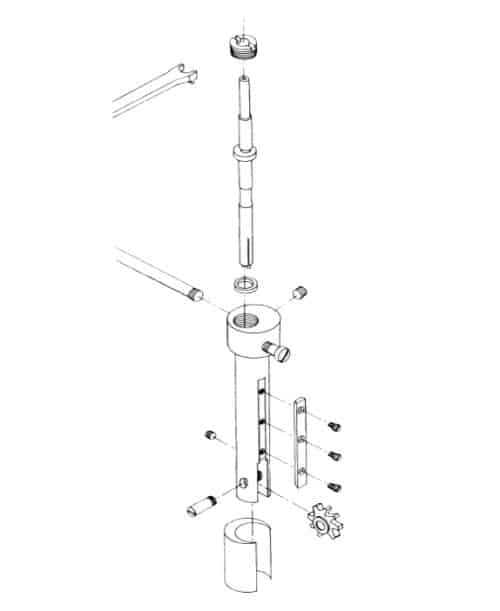

Utilizing the bore of your part and the Keyseat Miller to create a sliding fit, the Keyseat Miller feeds into the bore and mills a keyway in one pass to your prescribed width and depth.

As depicted in the video (below) a series of Driving Pins engage the back of the teeth of the Keyseat Cutter causing it to rotate.

Feeding the Keyseat Miller into your part- the keyway is completed! A simple and precise method to meet your internal keyway requirements.