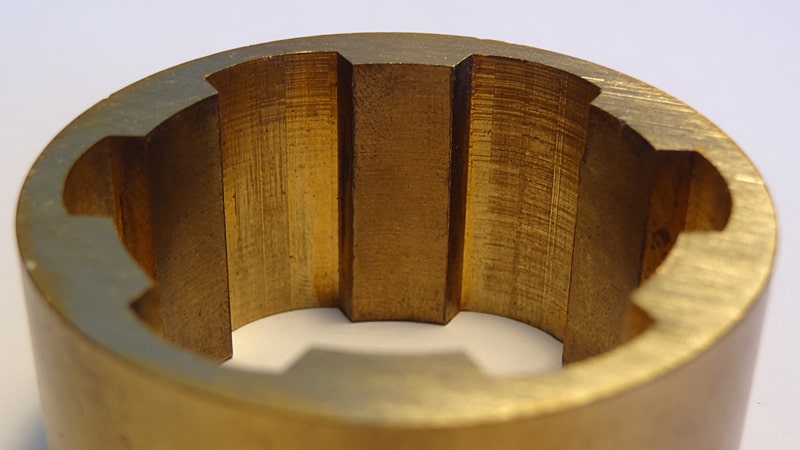

A customer in the food processing equipment business presented us with very interesting application for our tool. Our task at NMT was to design and develop a tool to mill 6 slots 60 degrees apart. Our solution was to create a unique Keyseat Miller designed with a sliding side location guide 60 degrees from the center line of the keyseat cutter. The first slot is milled conventionally. The part is then rotated 60 degrees, the location guide is secured (a simple set of 3 screws) to the body of the tool and then the side guide “becomes” the index to mill the remaining 5 cuts – each cut exactly 60 degrees from the one prior. The finished keyway dimensions were .500” in width and a depth of .187” with a .1505” radius arc. Extensive visual and dimensional inspections were conducted to ensure quality and functionality of the part. This project highlights our ability to design a tool to mill and index radiused slots.

For more information on this project, or the processes involved to manufacture it, see the table below or contact us directly.

Keyway Milling of a Stainless Steel Auger Project Highlights

- Product Name

-

Auger Keyseat Miller

- Problem Description

-

Part required 6 slots 60 degrees apart beginning 5 inches down in the part

- Solution

-

Special Keyseat Miller designed with side location guide 60 degrees from the centerline of cutter-mill first slot conventionally-attach location guide-rotate tool 60 degrees-location guide slides into first slot milled-process is repeated until all six slots are complete

- Capabilities Applied/Processes

-

Primary:

Engineering- Product Development/Design

CNC Milling

CNC Turning

Grinding

- Keyway Dimensions

-

Width: 0.500″

Depth: 0.187″ with Radius Arc

- Tightest Tolerances

-

Within 0.0002″

- Material Cut

-

440 Stainless Steel

- In process testing/inspection performed

-

Dimensional Inspection, Visual Inspection, Functionality

- Industry for Use

-

Food Processing Equipment Manufacturing

- Volume

-

1

- Delivery/Turnaround Time

-

Stock Items: 2 – 3 Days

Custom Items: 2 – 3 Weeks

- Delivery Location

-

Nationwide / Worldwide

- Standards Met

-

Customer Specifications, 2D CAD Drawing

(Click on thumbnail to enlarge)

(Click on thumbnail to enlarge)