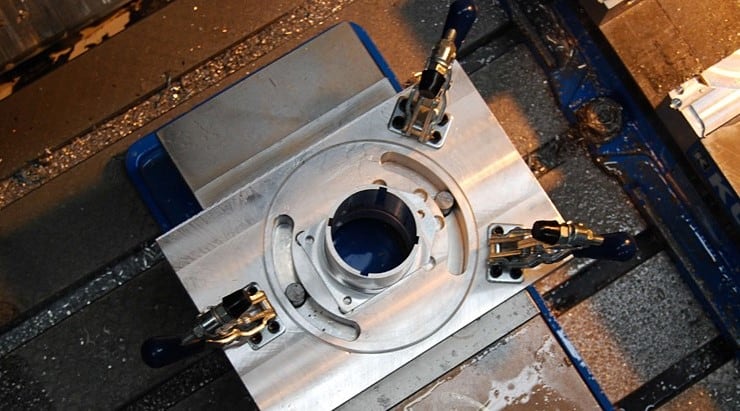

This project involved the manufacturing of a Keyseat Miller for a customer in the parts manufacturing industry. This customer has 4 keyways 90 degrees apart in a blind bore without a relief hole to break into. Our solution at NMT was to design and develop a special Keyseat Miller designed with a center mounted cutter. This cutter would mill two slots in one pass into the bore utilizing climb milling and conventional milling. The customer would then index the part and repeat the process and mill the other two slots. The keyway dimensions were .215” in width with a depth of .100”. The customer provided drawings called out the use of aluminum material and manufactured tolerances of +/- .0002” for this single unit. Functionality testing in addition to dimensional and visual inspections was completed to verify accuracy. This project highlights our versatility of tool design in a blind bore with multiple indexed slots.