Keyseating vs. Broaching: The Best Method for Internal Keyways

If you’re machining an internal keyway, your two main options are broaching and keyseating. Both work—but the right one depends on your part geometry, material, volume, and lead time.

In this quick guide, we break down the pros and cons of each so you can choose the right fit—and avoid unnecessary tooling costs or production delays.

Key Differences Between Broaching and Keyseating

| Feature | Broaching | Keyseating |

|---|---|---|

| Tooling Cost | High (custom broach required) | Low (standard cutter) |

| Setup Time | Long | Short |

| Blind Hole Compatible | ❌ | ✅ |

| Hardened Material Friendly | ❌ (limited) | ✅ |

| Best For | Large production runs | Prototypes, small runs, odd parts |

| Tolerance Range | ±0.002″–0.003″ typical | ±0.0015″ typical |

| Speed | Very fast (once tooled) | Moderate |

When to Use Broaching

✅ Use broaching when:

You’re producing hundreds or thousands of identical parts

You have a through-hole design

The material is mild steel or aluminum

You already have a broach tool built for the spec

But broaching breaks down when you’re dealing with:

Small batch or prototype work

Blind bores

Tight delivery schedules

Hardened materials (17-4, A2, Inconel)

Why Most Shops Switch to Keyseating

Keyseating is the flexible, low-cost alternative that works for 90% of internal keyway jobs we see.

It’s ideal when:

You don’t want to spend $2K+ on a broach tool

You’re cutting keyways in hardened or exotic materials

The part is a prototype, short-run, or rush job

The design includes a blind bore

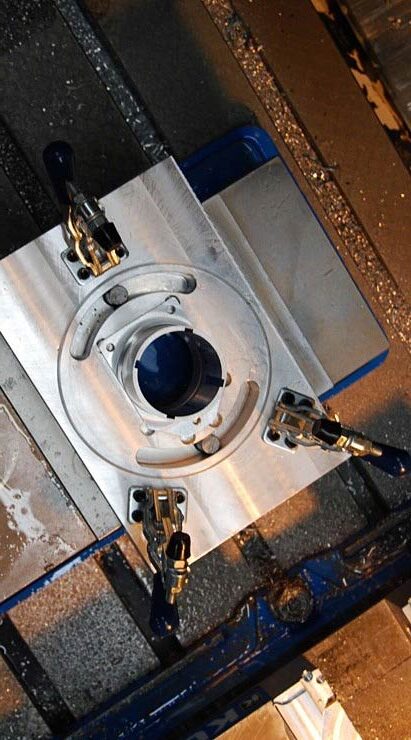

Plus, keyseating delivers superior straightness, less taper, and better control over slot depth—especially useful for couplings, gears, shafts, and drive hubs.

Industries We Serve

We provide keyway machining services for:

Aerospace

High-precision keyseating for aerospace parts and components.

Automotive

Machines capable of creating custom keyways for automotive transmission and engine parts.

Construction

Heavy-duty keyseating equipment suitable for demanding environments.

Energy & Utility

Machines for keyway cutting in power generation and utility equipment.

Still Not Sure? Send Us the Drawing.

We’ll review your part and tell you in plain English whether keyseating or broaching is better.

If we can machine it faster and cheaper, we will. If broaching’s the better fit—we’ll tell you.