Keyway Broaching for Stub Shafts

Stub shafts are essential components used in various mechanical systems, where reliable power transmission and precise alignment are critical. Keyway broaching offers a specialized machining method tailored to ensure seamless integration and optimal performance of stub shafts across diverse applications.

Understanding Keyway Broaching:

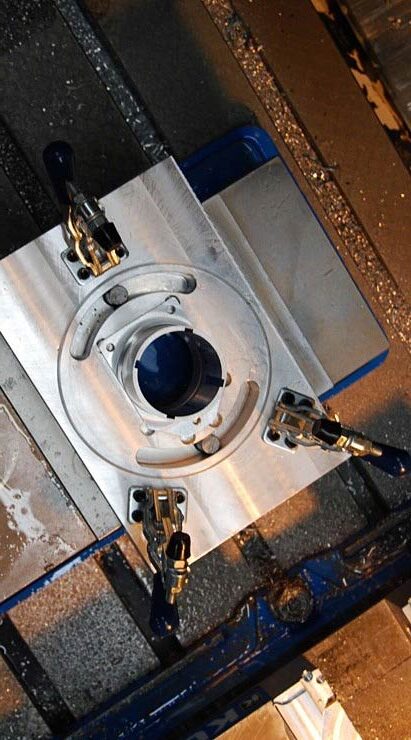

Keyway broaching is a precision machining process designed to create accurate keyways – slots or grooves – in shafts or hubs. These keyways serve as channels for securing components such as gears, pulleys, or couplings, ensuring precise alignment and efficient power transmission. In the context of stub shafts, keyway broaching enables the creation of precisely machined keyways for secure and reliable connections with other mechanical parts.

Importance of Precision in Stub Shaft Manufacturing:

Stub shafts serve as critical components in machinery where rotational motion is transferred from one component to another. Precision manufacturing of stub shafts is essential to ensure proper alignment, minimize vibration, and prevent premature wear. Keyway broaching allows for the creation of keyways with tight tolerances, ensuring smooth operation and optimal performance of mechanical systems.

Benefits of Keyway Broaching for Stub Shafts:

Accurate Alignment: Keyway broaching ensures precise alignment between the stub shaft and mating components, minimizing misalignment-related issues and maximizing efficiency.

Enhanced Strength: By creating uniform and precisely machined keyways, keyway broaching enhances the strength and durability of stub shafts, reducing the risk of premature failure.

Efficient Power Transmission: Well-defined keyways produced through keyway broaching minimize slippage and ensure efficient power transmission, contributing to the overall reliability of mechanical systems.

Tailored Solutions for Stub Shaft Applications:

Our state-of-the-art equipment and experienced machinists ensure the precise machining of keyways, meeting the exact specifications and requirements of our clients’ projects.